Thermal bridges represent a significant challenge in modern building design and construction. These areas of increased heat transfer can compromise the energy efficiency of even the most well-insulated structures, leading to higher energy costs and reduced occupant comfort. As the building industry strives for greater sustainability and energy performance, understanding and addressing thermal bridges has become crucial for architects, engineers, and builders alike.

The impact of thermal bridging on a building’s overall thermal performance can be substantial, with some estimates suggesting that up to 30% of a building’s heat loss can occur through these weak points in the thermal envelope. This not only affects energy consumption but also has implications for indoor air quality, moisture management, and the longevity of building materials.

Understanding thermal bridges: types and mechanisms

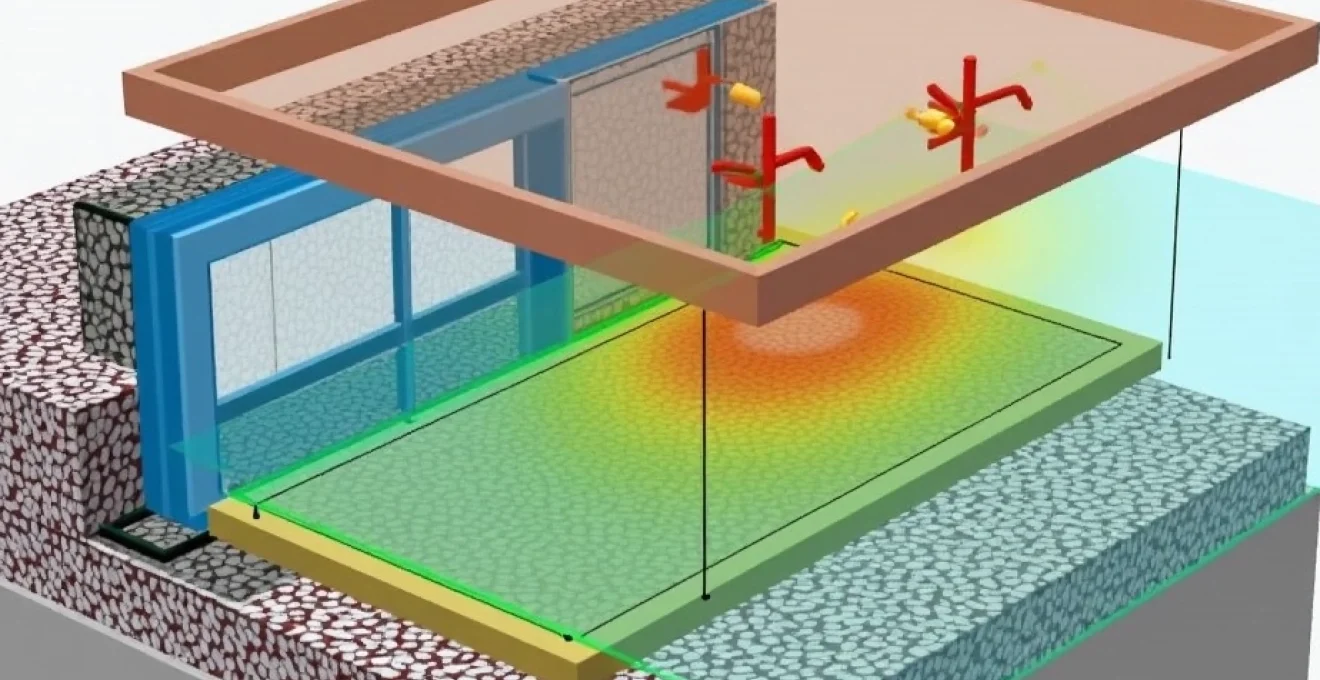

Thermal bridges are areas in a building’s envelope where heat flows more readily than through the surrounding areas. They occur when there is a break in the continuity of insulation or when materials with different thermal conductivities come into contact. The mechanisms behind thermal bridging are rooted in the fundamental principles of heat transfer: conduction, convection, and radiation.

There are several types of thermal bridges, each with its own characteristics:

- Geometric thermal bridges: These occur due to changes in the geometry of a building, such as corners or junctions between different building elements.

- Structural thermal bridges: Caused by structural elements that penetrate the insulation layer, like steel beams or concrete slabs.

- Systematic thermal bridges: Result from repeated elements in the building envelope, such as wall ties or fasteners.

- Convective thermal bridges: Areas where air movement allows heat to bypass the insulation layer.

Understanding these different types is essential for developing effective strategies to mitigate their impact on building performance. By identifying potential thermal bridges early in the design process, architects and engineers can implement solutions that maintain the integrity of the thermal envelope.

Quantifying energy loss through thermal bridging

To effectively address thermal bridging, it’s crucial to quantify its impact on a building’s energy performance. This process involves a combination of theoretical calculations and practical measurements, using various tools and methodologies to assess heat transfer through building assemblies.

Heat transfer coefficients and U-Values in building envelopes

The thermal performance of building elements is typically expressed through U-values, which measure the rate of heat transfer through a structure. Lower U-values indicate better insulation properties. However, standard U-value calculations often don’t account for the effects of thermal bridging, leading to an overestimation of a building’s thermal performance.

To accurately assess the impact of thermal bridges, designers use psi-values (Ψ-values) for linear thermal bridges and chi-values (χ-values) for point thermal bridges. These values quantify the additional heat flow caused by thermal bridges, allowing for a more precise calculation of a building’s overall heat loss.

Infrared thermography for detecting thermal bridges

Infrared thermography is a powerful tool for identifying and assessing thermal bridges in existing buildings. This non-invasive technique uses thermal imaging cameras to visualize temperature differences across building surfaces, highlighting areas of increased heat transfer.

Infrared imaging can reveal hidden thermal bridges that might otherwise go undetected, allowing for targeted improvements in building performance.

By conducting thermographic surveys under specific conditions, such as during cold weather with a significant temperature difference between indoor and outdoor environments, technicians can pinpoint areas of heat loss and quantify their impact on the building’s thermal performance.

Energy modelling software: THERM and WUFI passive

Advanced software tools play a crucial role in analyzing and predicting the effects of thermal bridging. Programs like THERM, developed by Lawrence Berkeley National Laboratory, allow designers to model two-dimensional heat transfer effects in building components. This enables detailed analysis of thermal bridges and the evaluation of different design solutions.

WUFI Passive, another sophisticated modelling tool, integrates thermal bridge analysis into whole-building energy simulations. This software can calculate the impact of thermal bridges on a building’s overall energy demand, helping designers optimize their strategies for minimizing heat loss.

Case studies: energy loss in residential vs. commercial buildings

The impact of thermal bridging can vary significantly between residential and commercial buildings due to differences in construction methods, materials, and building geometry. Case studies have shown that in some residential buildings, thermal bridges can account for up to 30% of total heat loss, particularly in older structures with poor insulation.

In commercial buildings, the situation can be even more complex. Large glazed facades, steel structures, and complex mechanical systems can create numerous opportunities for thermal bridging. A study of a modern office building found that addressing major thermal bridges reduced annual heating demand by 11%, demonstrating the significant potential for energy savings through targeted improvements.

Common thermal bridge locations in building construction

Identifying and addressing common thermal bridge locations is crucial for improving a building’s overall thermal performance. These weak points in the thermal envelope often occur at junctions between different building elements or where structural components penetrate the insulation layer.

Window and door frames: aluminium vs. PVC-U profiles

Window and door frames represent significant potential for thermal bridging, particularly in older buildings with less efficient framing materials. The choice of frame material can have a substantial impact on heat loss through these openings.

Aluminium frames, while durable and low-maintenance, have high thermal conductivity and can create significant thermal bridges if not properly designed. Modern aluminium frames often incorporate thermal breaks to mitigate this issue. In contrast, PVC-U (unplasticized polyvinyl chloride) profiles offer better inherent insulation properties, reducing the risk of thermal bridging.

A comparative study showed that high-performance PVC-U window frames can achieve U-values as low as 0.8 W/m²K, compared to 1.2 W/m²K for thermally broken aluminium frames, demonstrating the potential for energy savings through careful material selection.

Balcony attachments and cantilever structures

Balconies and cantilever structures present particularly challenging thermal bridging issues. Traditional balcony designs often involve a continuous concrete slab extending from the interior floor to the exterior, creating a direct path for heat transfer.

To address this, designers are increasingly turning to thermal break solutions. Products like Schöck Isokorb provide structural support while significantly reducing heat flow through the balcony connection. These innovative components can reduce heat loss at balcony junctions by up to 90%, dramatically improving the building’s thermal performance.

Roof-wall junctions and parapet details

The junction between a building’s roof and walls is another critical area for thermal bridging. Improper detailing at this interface can lead to significant heat loss and potential moisture problems. Parapets, in particular, can create complex thermal bridging issues if not carefully designed.

Effective solutions often involve ensuring continuity of insulation from the wall to the roof, using materials like rigid insulation boards that can be shaped to fit complex geometries. Some designers opt for warm roof constructions, where the insulation layer is placed above the roof structure, reducing the risk of thermal bridging at the eaves.

Foundation-to-wall connections: slab edge insulation

The connection between a building’s foundation and walls represents another potential weak point in the thermal envelope. Concrete slabs, in particular, can conduct significant amounts of heat if not properly insulated at the edges.

Slab edge insulation is a crucial strategy for mitigating this thermal bridge. By extending insulation down the edge of the slab and sometimes underneath it, designers can create a continuous thermal barrier that significantly reduces heat loss to the ground. The thickness and depth of this insulation can be optimized based on climate conditions and building design to achieve the best performance.

Innovative materials for thermal bridge mitigation

As the construction industry continues to prioritize energy efficiency, innovative materials are emerging to address the challenges posed by thermal bridging. These advanced solutions offer superior insulation properties and can be integrated into building designs to minimize heat loss through traditionally problematic areas.

Aerogel insulation: properties and applications

Aerogel, often referred to as “frozen smoke,” is one of the most exciting materials in the field of thermal insulation. This ultra-light substance, composed of up to 99.8% air, offers exceptional insulation properties with thermal conductivity values as low as 0.015 W/mK.

The unique properties of aerogel make it particularly useful for addressing thermal bridges in constrained spaces where traditional insulation materials would be impractical. For example, aerogel-based insulation can be applied in thin layers to window reveals or door frames, significantly reducing heat loss without compromising aesthetics or functionality.

Aerogel insulation can provide up to three times the thermal resistance of conventional insulation materials, making it a powerful tool for eliminating thermal bridges in complex building details.

Vacuum insulated panels (VIPs) in slim wall assemblies

Vacuum Insulated Panels (VIPs) represent another cutting-edge solution for thermal bridge mitigation. These panels consist of a porous core material enclosed in a gas-tight envelope from which the air has been evacuated. This results in an extremely low thermal conductivity, typically around 0.004 W/mK, making VIPs up to ten times more effective than conventional insulation materials of the same thickness.

VIPs are particularly valuable in situations where space is at a premium, such as in retrofitting projects or in the design of slim wall assemblies. By using VIPs, designers can achieve high levels of insulation performance without significantly increasing wall thickness, helping to maintain valuable floor space while dramatically improving thermal performance.

Phase change materials (PCMs) for thermal management

Phase Change Materials (PCMs) offer a dynamic approach to thermal management in buildings. These substances absorb and release thermal energy as they change phase, typically from solid to liquid and back again, at a specific temperature range.

While not directly addressing thermal bridging in the traditional sense, PCMs can help mitigate the effects of thermal bridges by stabilizing interior temperatures. By incorporating PCMs into building elements near thermal bridges, designers can create a thermal buffer that absorbs excess heat during warm periods and releases it when temperatures drop, effectively smoothing out temperature fluctuations caused by thermal bridging.

Structural thermal breaks: schöck isokorb and armatherm

Structural thermal breaks are engineered components designed to provide load-bearing capacity while minimizing heat transfer across building elements. Products like Schöck Isokorb and Armatherm are specifically developed to address thermal bridging in challenging areas such as balcony connections, canopies, and steel beam penetrations.

These components typically consist of high-strength, low-conductivity materials that can withstand structural loads while providing significant thermal resistance. For example, the Schöck Isokorb system can reduce heat loss at balcony connections by up to 90% compared to uninsulated concrete slabs, dramatically improving overall building performance.

Design strategies for eliminating thermal bridges

Effective mitigation of thermal bridges requires a holistic approach to building design, integrating thermal performance considerations from the earliest stages of the project. By adopting a comprehensive strategy, architects and engineers can create buildings that are not only energy-efficient but also comfortable and durable.

Key design strategies for eliminating thermal bridges include:

- Continuous insulation: Ensure that insulation layers are uninterrupted across the building envelope, using techniques such as exterior insulation and finish systems (EIFS) or rainscreen cladding systems.

- Thermal break materials: Incorporate low-conductivity materials at junctions between building elements to minimize heat transfer.

- Optimized structural design: Minimize penetrations of the insulation layer by structural elements, using techniques such as thermally optimized steel framing or advanced wood framing methods.

- Careful detailing: Develop and implement detailed drawings for all critical junctions in the building envelope, ensuring that thermal continuity is maintained.

- Performance modeling: Utilize advanced energy modeling software to analyze the impact of design decisions on thermal bridging and overall building performance.

By implementing these strategies, designers can create buildings that not only meet but exceed energy performance standards, contributing to a more sustainable built environment.

Regulatory standards and performance metrics for thermal bridging

As awareness of the impact of thermal bridging has grown, regulatory bodies and certification programs have begun to incorporate specific requirements and performance metrics related to thermal bridge mitigation. These standards provide a framework for assessing and improving building thermal performance.

Passivhaus certification requirements for thermal Bridge-Free design

The Passivhaus (Passive House) standard, developed in Germany and now adopted worldwide, sets stringent requirements for building energy performance, including specific criteria for thermal bridge-free design. To achieve Passivhaus certification, buildings must demonstrate that thermal bridging has been minimized to the point where its impact on overall heat loss is negligible.

Specifically, the Passivhaus standard requires that linear thermal transmittance (Ψ-value) for any thermal bridge must not exceed 0.01 W/mK. Achieving this level of performance often necessitates detailed thermal modeling and innovative design solutions, pushing the industry towards more energy-efficient practices.

ASHRAE 90.1 and IECC guidelines on thermal bridging

In North America, standards such as ASHRAE 90.1 and the International Energy Conservation Code (IECC) have begun to address thermal bridging more explicitly in recent editions. While not as stringent as Passivhaus requirements, these standards now include provisions for continuous insulation and mitigation of major thermal bridges.

For example, ASHRAE 90.1-2019 introduced new requirements for envelope commissioning, which includes verification of thermal bridge mitigation strategies. The IECC 2021 edition also emphasizes the importance of continuous insulation and provides guidance on addressing thermal bridging in various building assemblies.

Bre’s SAP calculations and Psi-Values for UK building regulations

In the United Kingdom, the Building Research Establishment’s (BRE) Standard Assessment Procedure (SAP) is used to assess the energy performance of dwellings. SAP calculations now incorporate psi-values to account for the impact of thermal bridging on overall building performance.

The UK Building Regulations require that thermal bridging be addressed either through the use of Accredited Construction Details (ACDs) or through the calculation of specific psi-values for each thermal bridge in the building. This approach has led to increased attention to thermal bridging in UK building design and has driven improvements in construction practices.

As regulatory standards continue to evolve, it’s clear that addressing thermal bridging will become an increasingly important aspect of building design and construction. By staying ahead of these requirements and implementing best practices for thermal bridge mitigation, designers and builders can create more energy-efficient, comfortable, and sustainable buildings that meet the challenges of a changing climate.