Geothermal heat pumps represent a revolutionary approach to heating and cooling buildings, leveraging the earth’s constant temperature to provide efficient, sustainable climate control. This innovative technology taps into the natural thermal energy stored just beneath our feet, offering a reliable alternative to traditional HVAC systems. As the world increasingly seeks eco-friendly solutions, geothermal heat pumps stand out for their ability to significantly reduce energy consumption and carbon emissions while providing year-round comfort.

Principles of geothermal heat pump technology

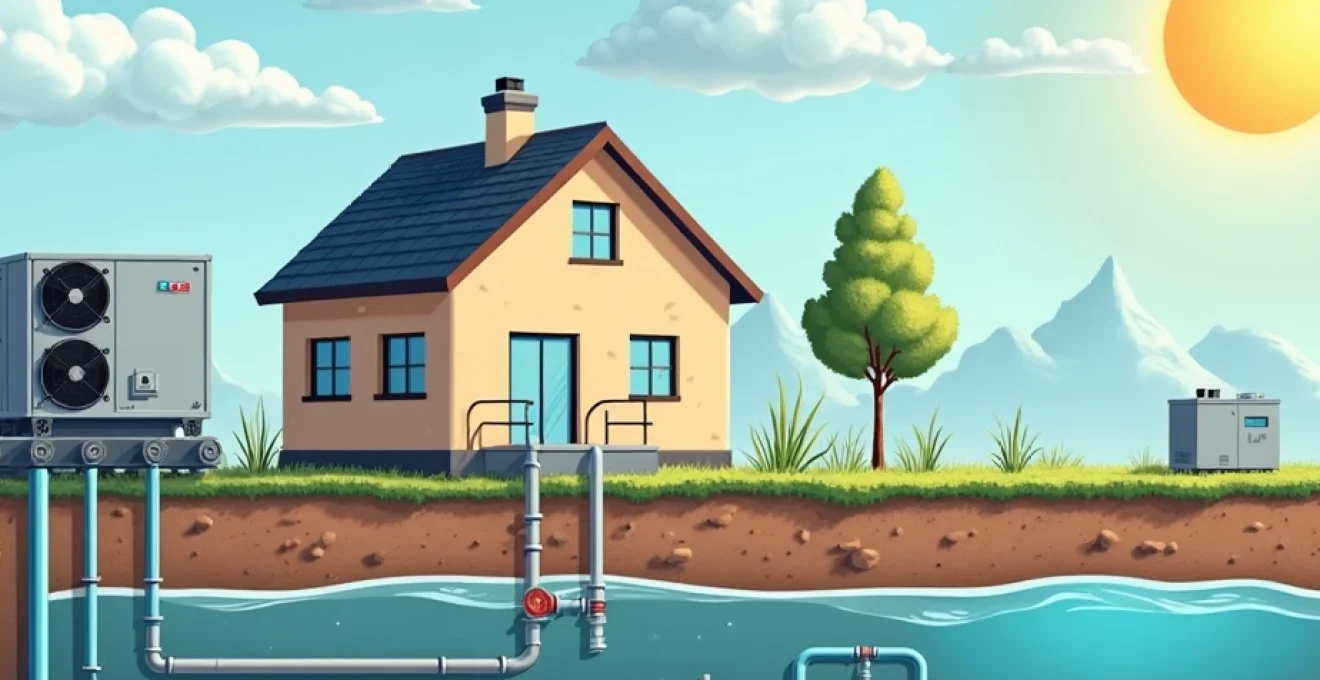

At its core, geothermal heat pump technology relies on the principle that the earth maintains a relatively stable temperature throughout the year. This consistency is key to the system’s efficiency. Unlike air-source heat pumps that struggle with extreme outdoor temperatures, geothermal systems exchange heat with the ground, which remains at a near-constant temperature of about 10-16°C (50-60°F) just a few metres below the surface.

The process works by circulating a fluid, typically a mixture of water and antifreeze, through a network of underground pipes. In winter, this fluid absorbs heat from the warmer ground and transfers it into the building. During summer, the process reverses, with the system extracting heat from the building and depositing it into the cooler earth.

This heat exchange is made possible through a heat pump , which uses a small amount of electricity to move heat from one place to another. The efficiency of this process is remarkable, with geothermal systems often delivering 3-5 units of heating or cooling for every unit of electricity consumed.

Ground source heat exchanger systems: vertical vs horizontal loops

The heart of any geothermal heat pump system lies in its ground heat exchanger. There are two primary configurations for these underground networks: vertical and horizontal loops. Each has its own set of advantages and is suited to different site conditions.

Vertical Closed-Loop borehole heat exchangers

Vertical systems consist of pipes that run straight down into the earth, typically to depths of 50-150 metres. These are ideal for properties with limited land area or where minimal surface disruption is desired. Vertical loops offer consistent performance due to the stable ground temperature at depth and are less affected by seasonal temperature fluctuations.

Vertical systems are particularly effective in commercial applications where high heating and cooling loads are required, as they can tap into deeper, more stable ground temperatures.

The installation process involves drilling several boreholes and inserting U-shaped pipes, which are then grouted in place to ensure good thermal contact with the surrounding earth. While initially more expensive due to drilling costs, vertical systems often provide superior long-term performance.

Horizontal slinky coil ground heat exchangers

Horizontal systems, in contrast, involve laying pipes in trenches about 1-2 metres deep. The slinky coil configuration maximizes the pipe length within a given area, enhancing heat transfer. This method is generally more cost-effective for residential installations where sufficient land is available.

Horizontal loops require more land area than vertical systems but are easier and cheaper to install. They’re particularly suited to new construction projects where groundwork is already being undertaken. However, their performance can be slightly affected by seasonal temperature changes in the upper soil layers.

Direct exchange (DX) geothermal systems

Direct exchange systems represent a more specialized approach to geothermal heating and cooling. In DX systems, refrigerant circulates directly through copper tubing buried in the ground, eliminating the need for an intermediate heat exchanger.

This direct contact between refrigerant and earth results in highly efficient heat transfer. However, DX systems require careful design to prevent refrigerant leaks and may face regulatory challenges due to environmental concerns about refrigerants in direct contact with soil.

Groundwater and surface water heat pump systems

In areas with abundant water resources, groundwater or surface water can serve as excellent heat exchange mediums. These open-loop systems pump water directly from a well or body of water, pass it through a heat exchanger, and return it to its source.

Water-source heat pumps can be extremely efficient due to water’s excellent heat transfer properties. However, they require a reliable water source and must comply with local regulations regarding water use and discharge.

Geothermal heat pump components and operation

Understanding the key components and operation of geothermal heat pumps is crucial for appreciating their efficiency and reliability. Let’s delve into the core elements that make these systems work.

Refrigerant cycle in ground source heat pumps

The refrigerant cycle is the backbone of heat pump operation. In a geothermal system, the refrigerant undergoes phase changes to absorb and release heat efficiently. The cycle typically involves four stages:

- Evaporation: Liquid refrigerant absorbs heat from the ground loop fluid and vaporizes

- Compression: The vapor is pressurized, raising its temperature

- Condensation: The hot vapor releases heat to the building and condenses

- Expansion: The liquid refrigerant depressurizes, cooling rapidly to restart the cycle

This continuous cycle allows the heat pump to move heat from the ground into the building (or vice versa) with remarkable efficiency.

Compressor technologies: scroll vs reciprocating

The compressor is a critical component in any heat pump system. Two main types are commonly used in geothermal units: scroll and reciprocating compressors.

Scroll compressors use two interleaving spiral-shaped scrolls to compress refrigerant. They’re known for their quiet operation, high efficiency, and reliability. Scroll technology has become increasingly popular in geothermal systems due to its smooth operation and ability to handle varying loads efficiently.

Reciprocating compressors , on the other hand, use a piston-cylinder mechanism. While they’re generally less expensive, they tend to be noisier and slightly less efficient than scroll compressors. However, they can still be found in some geothermal heat pump models, particularly in smaller residential systems.

Heat exchanger types: plate, Shell-and-Tube, and coaxial

Heat exchangers facilitate the transfer of thermal energy between the refrigerant and the ground loop fluid or building distribution system. Three common types are used in geothermal heat pumps:

- Plate heat exchangers: Consist of multiple thin plates that maximize surface area for efficient heat transfer

- Shell-and-tube exchangers: Use a bundle of tubes within a larger shell, offering robust performance for larger systems

- Coaxial (tube-in-tube) exchangers: Feature one tube inside another, providing efficient heat transfer in a compact design

Each type has its advantages, with selection depending on factors such as system size, fluid properties, and pressure requirements.

Reversing valves and defrost cycles

Reversing valves are crucial components that allow geothermal heat pumps to switch between heating and cooling modes. By redirecting the flow of refrigerant, these valves effectively reverse the heat pump’s operation, allowing it to extract heat from the building in summer and deliver heat in winter.

In colder climates, defrost cycles may be necessary to prevent ice buildup on outdoor components of air-source heat pumps. However, geothermal systems typically don’t require defrost cycles, as the ground temperature remains above freezing year-round, contributing to their superior efficiency in cold weather.

Efficiency metrics and performance factors

Evaluating the performance of geothermal heat pumps requires understanding several key efficiency metrics. These measurements help in comparing different systems and assessing their potential energy savings.

Coefficient of performance (COP) calculation

The Coefficient of Performance (COP) is a crucial metric for assessing heat pump efficiency. It represents the ratio of heat output to electrical energy input. For geothermal systems, COPs typically range from 3 to 5, meaning they produce 3 to 5 units of heat for every unit of electricity consumed.

The COP calculation is as follows:

COP = Heat Output (kW) / Electrical Input (kW)

A higher COP indicates greater efficiency. Geothermal heat pumps often achieve higher COPs than air-source systems due to the stable ground temperatures they utilize.

Energy efficiency ratio (EER) for cooling mode

While COP is used for heating performance, the Energy Efficiency Ratio (EER) measures cooling efficiency. EER is calculated by dividing the cooling output (in BTUs per hour) by the power input (in watts).

EER = Cooling Output (BTU/h) / Power Input (W)

Geothermal systems typically have EERs ranging from 15 to 25, significantly higher than most conventional air conditioning systems.

Seasonal energy efficiency ratio (SEER) considerations

The Seasonal Energy Efficiency Ratio (SEER) provides a more comprehensive measure of cooling efficiency over an entire season. It accounts for variations in outdoor temperatures and part-load performance. While SEER is more commonly used for air-source systems, it can also be applied to geothermal heat pumps.

Geothermal systems often achieve SEER ratings of 20 or higher, outperforming most conventional cooling systems. This high efficiency translates to significant energy savings over the cooling season.

Ground temperature influence on system efficiency

The efficiency of a geothermal heat pump is closely tied to ground temperature. In most locations, the earth maintains a relatively constant temperature year-round at depths of a few metres. This stability provides geothermal systems with a consistent source of heat in winter and a reliable heat sink in summer.

As ground temperatures vary less than air temperatures, geothermal heat pumps maintain high efficiency levels throughout the year. This contrasts with air-source heat pumps, which struggle in extreme temperatures, particularly in heating mode during very cold weather.

Installation considerations and site assessment

Proper installation is crucial for the performance and longevity of a geothermal heat pump system. A thorough site assessment is the first step in ensuring an optimal installation.

Key factors to consider during site assessment include:

- Available land area for ground loops

- Soil composition and thermal properties

- Groundwater levels and flow

- Local geology and potential for rock excavation

- Existing utilities and underground structures

Professional installers use specialized software to model the thermal characteristics of the site and design an appropriately sized system. This includes determining the required loop length, borehole depth, or trench dimensions based on the building’s heating and cooling loads.

Installation costs can vary significantly depending on the chosen system type and site conditions. While geothermal systems generally have higher upfront costs than conventional HVAC systems, their long-term energy savings and durability often result in favorable life-cycle costs.

Proper installation by certified professionals is essential for ensuring system performance and avoiding issues such as improper loop sizing or inadequate grouting, which can significantly impact efficiency and longevity.

Environmental impact and sustainability of geothermal systems

Geothermal heat pumps offer substantial environmental benefits compared to conventional heating and cooling systems. By harnessing the earth’s natural heat, they significantly reduce reliance on fossil fuels and minimize greenhouse gas emissions.

The environmental advantages of geothermal systems include:

- Reduced carbon footprint: Geothermal heat pumps can reduce a building’s carbon emissions by up to 70% compared to conventional systems

- Energy efficiency: With COPs of 3-5, geothermal systems use far less energy than traditional HVAC equipment

- Longevity: The underground components of geothermal systems can last 50+ years, reducing waste and resource consumption

- Minimal land use: Once installed, geothermal systems have little to no visible impact on the landscape

- Water conservation: Closed-loop systems do not consume water, unlike some cooling towers used in conventional systems

Moreover, as electricity grids increasingly incorporate renewable energy sources, the environmental benefits of geothermal heat pumps will continue to grow. By using electricity more efficiently than conventional heating and cooling systems, geothermal technology supports the transition to a cleaner, more sustainable energy future.

In conclusion, geothermal heat pumps represent a powerful tool in the quest for sustainable, efficient building climate control. As you consider options for heating and cooling your home or business, the long-term benefits of geothermal technology – from energy savings to environmental stewardship – make it a compelling choice for the future of HVAC.